LTPRUP series

90W strobe LED pattern projectors

As of September 30, 2024, LTPRUP series will be replaced by LT2PRUP series: for further details, please refer to the Product Discontinuation Notice.

Key advantages

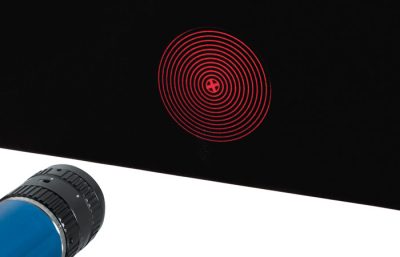

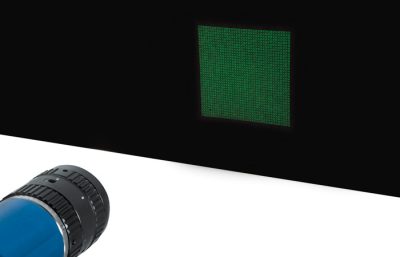

- LED technology for perfectly sharp edges

Thinner lines, sharper edges and more even illumination than lasers - Ultra high-power light output and strobe mode only operation

Low sensitivity to ambient light for the inspection of fast moving objects and an extended LED lifetime - Repeatable results with dedicated strobe controllers

Compatible LTDV series ensures very stable illumination intensity - Wide selection of projection patterns available (custom-made upon request)

Chrome-on-glass patterns with geometrical accuracy down to 2 μm - Compatible with any C-mount optics

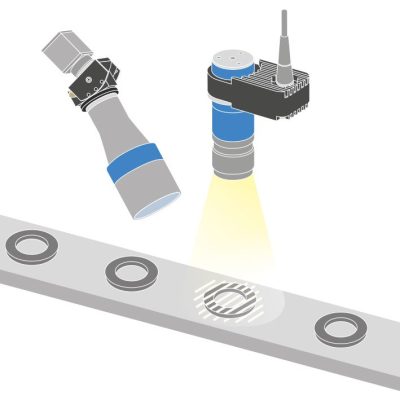

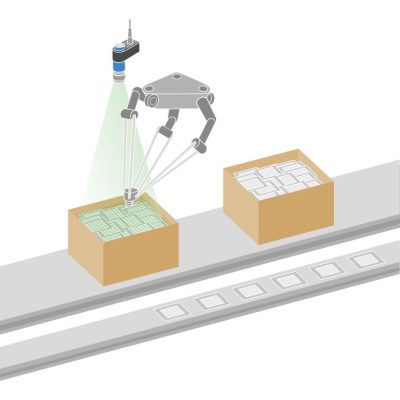

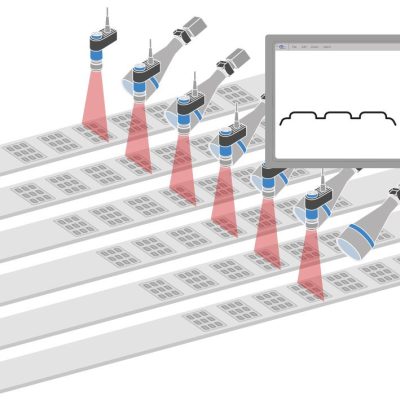

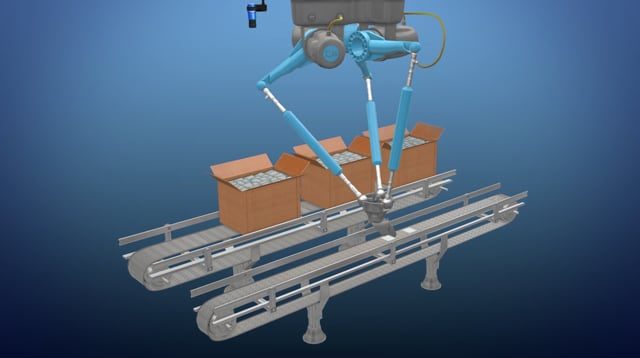

The LTPRUP series features the most powerful LED pattern projectors designed for fast image acquisition in high-speed applications where the camera exposure time must be set to the minimum, including planarity control of opaque products, robot guidance for fast pick and place and 3D profiling.

LTPRUP projectors are strobe only and provide ultra-high intensity while ensuring extended LED lifetime and reduced heat generation.

The LTPRUP series is current driven and can be precisely controlled using our LTDV strobe controllers series. LTDV controllers are designed to drive the LED of LTPRUP pattern projectors with perfectly constant current, ensuring repeatable results even in applications where low exposure time is required. This minimizes illumination intensity variations down to ± 1%, leading to accurate and repeatable results when compared to models offered by major competitors.

Additionally, rise and fall times are kept to the minimum: this ensures repeatable results specifically in applications where light intensity is controlled through time-dimming.

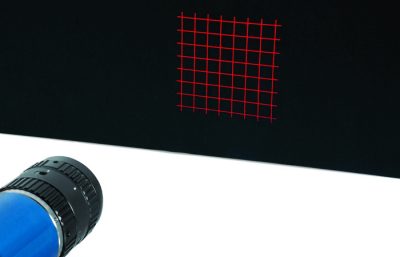

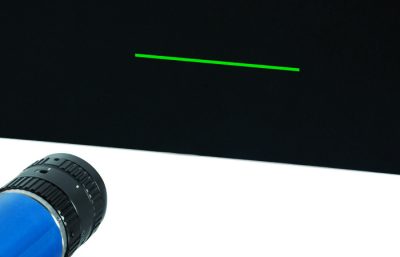

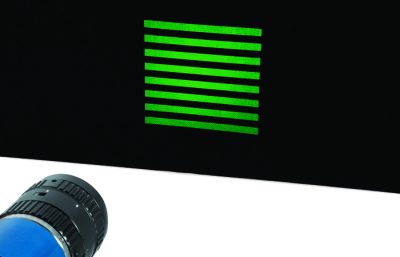

Multiple interchangeable patterns, either stripe or grid styles, are available along with optional custom patterns.

Real-world application examples and case histories

Application examples

Notes

- With a 35 mm lens, F/N 1.4 at 100 mm working distance without projection pattern at maximum driving current. Estimated value.

- To directly drive the LED, current control is necessary. External compatible controller from LTDV series must be used.

- At 25°C. At max pulse width (1 ms), max pulse frequency = 15 Hz. Contact us to check other admissible combinations of duty cycle-frequency-temperature.

- At 25° C.

- Including connector.

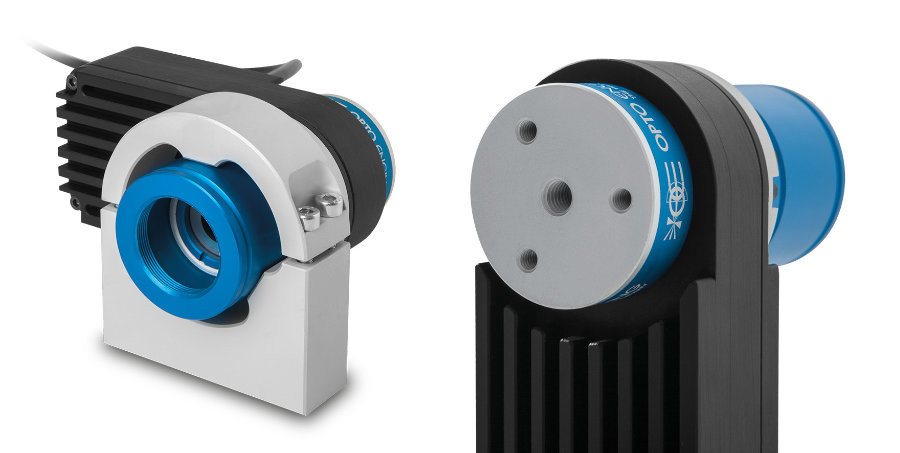

LTPRUP pattern projectors can be easily integrated into any vision system thanks to their compact design, multiple threaded holes positioned in the rear part, and compatibility with CMHO016 clamping mechanics. Additionally, the phase-adjustment design allows for easy pattern alignment.

LTPRUP-x models for strobe-only operation featuring ~ 90W peak power intensity. These models are compatible with CMHO016 clamping mechanics, alternatively, three M4 and one M6 threads are available as fixing options.

Projection lens selection

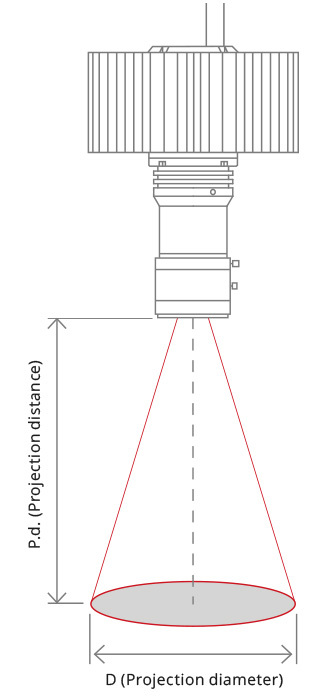

Any C-mount optics for 2/3” sensors (11 mm image diagonal) can be interfaced with LTPRUP series to project areas with different sizes. Unless the projection optics introduces significant distortion, the shape of the projected pattern will preserve the features and aspect ratio of the engraved pattern.

The projected area dimensions will be “M” times the original dimensions of the pattern, where M is the optical magnification at which the selected projection lens is operating.

Telecentric lenses for 2/3” sensors can also be interfaced with LTPRUP models, thus providing telecentric projection of the pattern and enabling unparalleled performance in 3D measurement applications.

2-3″ C-mount lenses

| P.D. | @50 | @75 | @100 | @150 | @200 | @250 | @300 | @400 | @500 |

|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| Focal length |

D (Projection diameter) (mm) |

||||||||

| 6 mm | 81 | 127 | 172 | 264 | |||||

| 8 mm | 58 (*) | 92 | 127 | 195 | 264 | 333 | |||

| 12 mm | 35 (*) | 58 (*) | 81 | 127 | 172 | 218 | 264 | ||

| 16 mm | 41 (*) | 58 (*) | 92 (*) | 127 | 161 | 195 | 264 | 333 | |

| 25 mm | 55 (*) | 77 (*) | 99 (*) | 121 (*) | 165 | 209 (*) | |||

| 35 mm | 68 (*) | 83 (*) | 115 | 146 | |||||

(*) = spacers may be needed to compensate back focal length

Telecentric lenses

| TC23004 | TC23007 | TC23009 | TC23016 | TC23024 | TC23036 | |

|---|---|---|---|---|---|---|

| P.d.(mm) | 56.0 | 60.1 | 62.2 | 43.1 | 67.2 | 102.5 |

| D.(mm) | 5.5 | 8.3 | 11.0 | 20.8 | 31.4 | 45.2 |

| TC23048 | TC23056 | TC23064 | TC23072 | TC23080 | TC23096 | |

| P.D.(mm) | 132.9 | 157.8 | 181.8 | 226.7 | 226.7 | 278.6 |

| D.(mm) | 59.8 | 70.0 | 80.0 | 89.9 | 99.7 | 117.8 |

Pattern selection

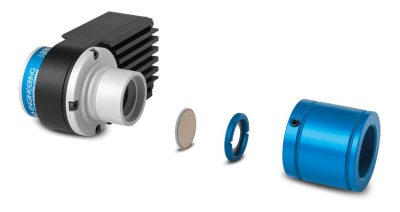

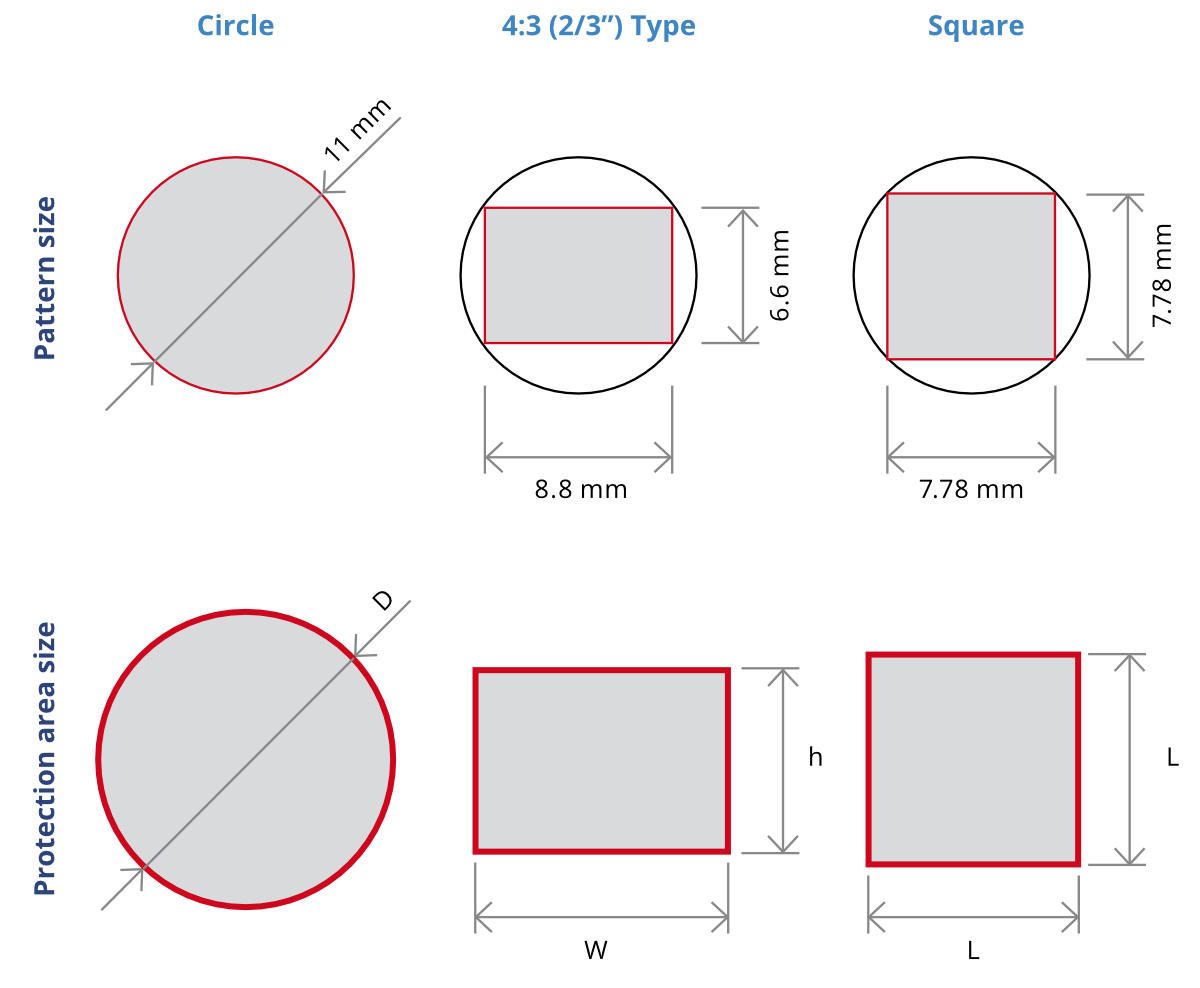

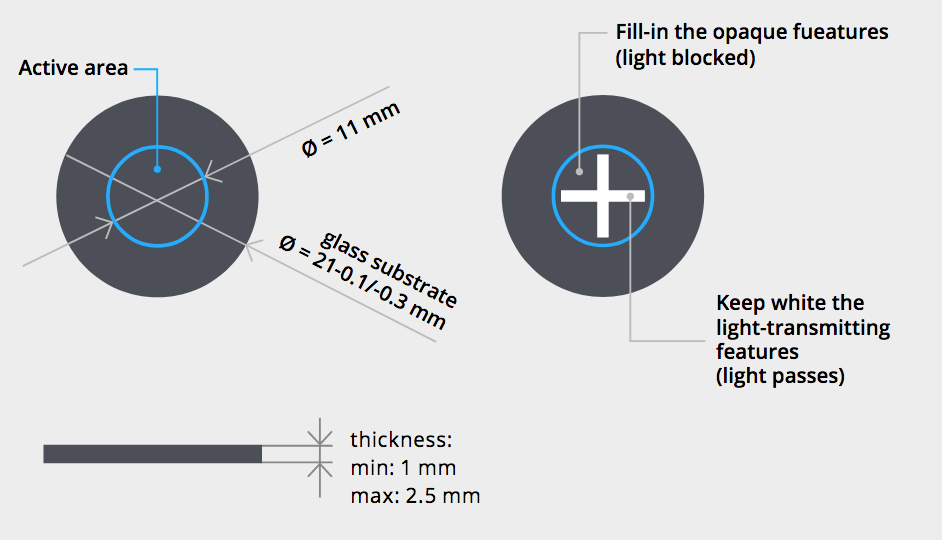

The projection pattern can be easily interchanged by unscrewing the retaining ring that holds the pattern. The pattern outer diameter is 21 mm, while the active projection area is a circle of Ø 11 mm.

The pattern drawing could either cover the entire 11 mm diameter area or be of any shape inscribed within this area (such as a 7.78x7.78 mm square or an 8.8 x 6.6 mm rectangle). The projection accuracy depends both on the pattern manufacturing accuracy and the distortion of the projection lens mounted on the projector.

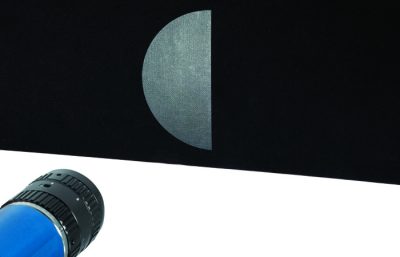

The edge sharpness of the projected pattern depends on both the resolving power of the lens and the engraving technique: laser-engraved patterns (part numbers ending in “L”) or photolithography-engraved patterns (part numbers ending in “P”) can be chosen depending on the type of application.

Standard patterns

Custom-made patterns

Custom-made patterns can be supplied on request. A drawing with accurate geometrical information must be submitted (please refer to the instructions here below).