LT2PRXP series

40W continuous and strobe LED pattern projectors

Key advantages

- High efficiency LEDs for sharp edges, superior homogeneity and contrast

- Built-in driver for continuous and strobe operations

- 5 PIN M12 connector with PNP/NPN/analog dimming input

- Compatible with standard C-mount lenses up to 1.1”

- Automatic shutdown in case of overheating

- Interchangeable projection patterns

- Compact version available

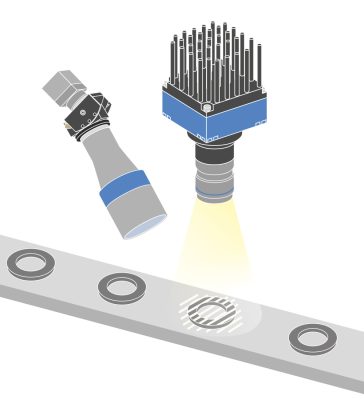

The LT2PRXP series features high-power LED pattern projectors designed for inline or offline applications including quality control, 3D reconstruction, dimensional measurement, planarity control, robot guidance and alignment applications.

Featuring high-efficiency LEDs, they provide very high intensity and homogeneous light output.

LT2PRXP pattern projectors are available in two different versions to meet diversified application needs. The standard version integrates a built-in driver for continuous and strobe mode operations ensuring great application flexibility. The compact version is a projector designed for strobe mode only operations and ideal for applications with space constraints.

LT2PRXP projectors feature a standard 5-pin M12 connector with PNP/NPN/analog dimming input, ideal for industrial environments.

The aluminum heat sink is designed to dissipate heat ensuring long lifetime of the LED module and driving electronics, even at the highest power rates. The integrated temperature sensor ensures automatic shut-down in case of overheating.

LT2PRXP series is available in different colors and features a wide selection of interchangeable projection patterns (see PTPR series) which can be easily integrated to project any kind of shape.

Did you know?

Unlike laser sources, which typically show poor line sharpness and power distribution as well as scattering, speckle and diffraction effects, our pattern projectors integrate LED sources and precisely engraved patterns ensuring thinner lines, sharper edges and more homogeneous illumination.

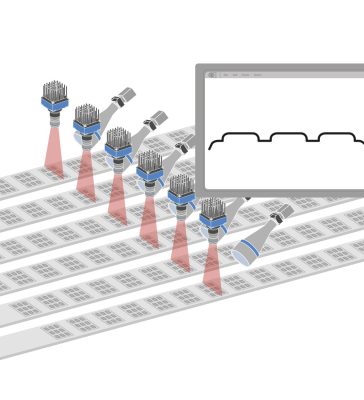

Applications examples

- Inspection of pharmaceutical blisters for volume control

- Robot guidance for fast pick-&-place

- 3D reconstruction in the electronics and semiconductor industry

- Identification of deformations on components with complex structures

- Alignment applications

Notes

- At pattern emitting surface.

- Continuous mode, using the integrated electronic driver.

- Strobe mode.

Technical documents

Comparing LED pattern projectors

Model |

Integrated driver |

Passive cooling |

Compact shape |

5-pin M12 connector |

Built-in temperature sensor |

Continuous mode | Strobe mode | Projection lens | Power |

LTPRHP3W |

✓* |

✓ | ✓ |

✕ |

✕ |

✓ | ✓** | Up to 2/3" | Low |

LTPRSMHP3W |

✓* |

✓ | ✓ |

✕ |

✕ |

✓ | ✓** | Up to 2/3" | Low |

LT2PRXP |

✓ |

✓ |

✕ |

✓ |

✓ |

✓ | ✓ | Up to 1.1" | Medium |

LT2PRXP‑C |

✕ | ✓ |

✓ |

✓ |

✓ |

✕ | ✓** | Up to 1.1" | Medium |

LT2PRUP |

✓ |

✓ |

✕ |

✓ |

✓ |

✓ | ✓ | Up to 1.1" | High |

| * Controls only continuous operation mode | |||||||||

| ** Only with external driver | |||||||||