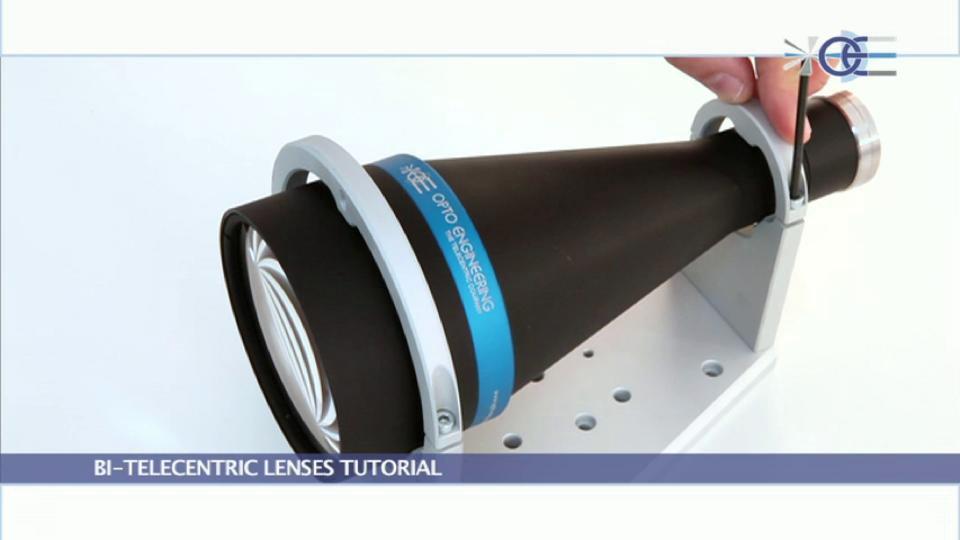

TC16M series

Telecentric lenses for sensors up to 43.3 mm and 8k line scan cameras

As of July 31, 2023, TC16M009, TC16M009-Q and TC16M009-K models of TC16M series will be discontinued. For further details, please refer to the Product Discontinuation Notice.

New size 308 now available: TC16M Series is now available also for fields of view up to 372 mm in diameter.

Key advantages

- Wide image circle for large detectors up to 43.3 mm.

- Excellent resolution and low distortion

- Simple and robust design for industrial environments

- Detailed test report with certified optical parameters

TC16M series telecentric lenses have been specifically designed to fit 45 mm format (36 x 24 mm) detectors with very high resolution, such as 11, 16 or 29 MP

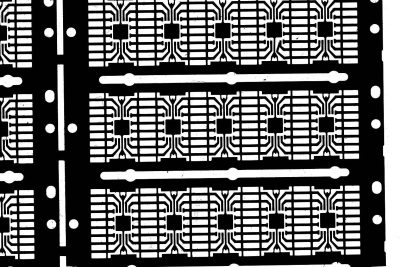

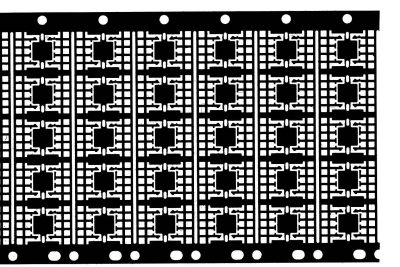

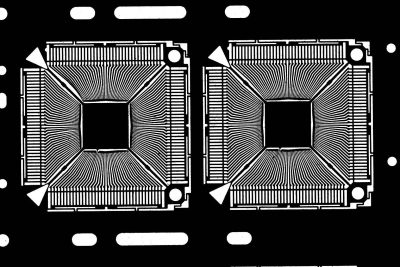

This combination is the typical choice for extremely accurate measurement of large items such as engine parts, glass or metal sheets, PCBs and electronic components, LCDs, etc.

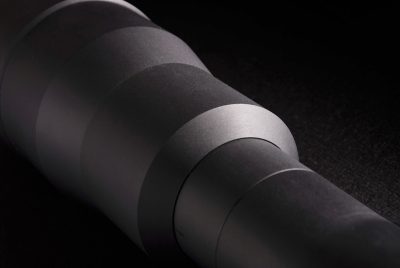

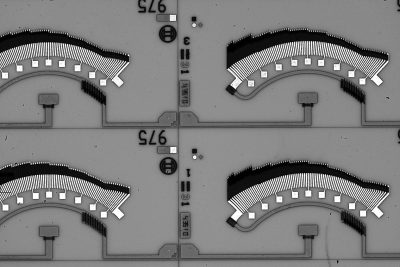

TC16M lenses are also perfectly suitable for 4kpx and 8kpx line scan cameras and can be successfully used to determine the diameter of cylindrical objects: for example shafts, turned metal parts, machine tools, etc.

Besides the standard F and M58x0.75 mount options, any other mechanical interface can be supplied upon request

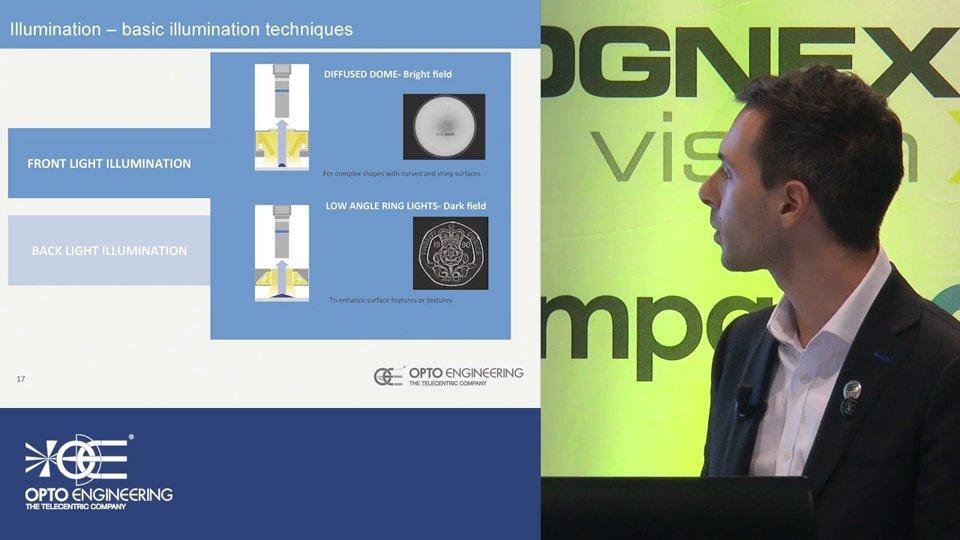

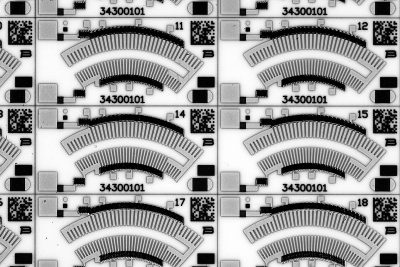

Real-world application examples and case histories

Notes

- Working distance: distance between the front end of the mechanics and the object. Set this distance within ±3% of the nominal value for maximum resolution and minimum distortion.

- Working f-number (wf/N): the real f-number of a lens in operating conditions.

- Maximum angle between chief rays and optical axis on the object side. Typical (average production) values and maximum (guaranteed) values are listed.

- Percent deviation of the real image compared to an ideal, undistorted image. Typical (average production) values and maximum (guaranteed) values are listed.

- At the limits of the depth of field, the image can still be used for measurements. For a very sharp image, however, only half of the depth of field should be considered. Pixel size used for calculation is 5.5 μm.

- Object side, calculated with the Rayleigh criterion with λ= 520 nm

- FD stands for Flange Distance (in mm), defined as the distance from the mounting flange (the “metal ring” in rear part of the lens) to the camera detector plane.

- Indicates the availability of an integrated camera phase adjustment feature.

- Measured from the front end of the mechanics to the camera flange.