LTCLHP CORE series

Compact telecentric illuminators

Key advantages

- Deliver excellent performances

LTCLHP CORE telecentric illuminators deliver exactly the same excellent optical performances as other Opto Engineering® telecentric illuminators. - Downsize your vision system

LTCLHP CORE telecentric illuminators are up to 60% smaller than other telecentric illuminators on the market. - Easy retrofitting into existing systems

LTCLHP CORE illuminators can be mounted in different directions in your machine. - Improve your system performances

LTCLHP CORE illuminators may be used instead of flat backlights to improve your system. - Cut costs and sell more

A smaller system means less expenses and less space and is preferred by the industry. - Homogeneity test report with measured values

The LTCLHP CORE Series offers ultra compact telecentric illuminators. They are up to 60% more compact than other collimated illuminators on the market.

The ultra compact size allows to greatly reduce the size of your machine and to easily integrate true collimated illumination instead of common flat backlights, thus improving your system’s performance.

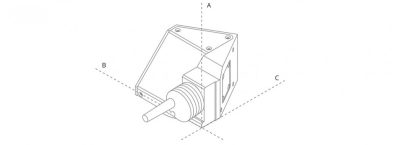

The smart design also makes them easy to retrofit into existing systems. They can easily be mounted in different directions using any of their 4 sides, with or without clamps.

A smaller system means lower manufacturing, shipping and storage costs, as well as less use of factory space and is the solution preferred by the industry.

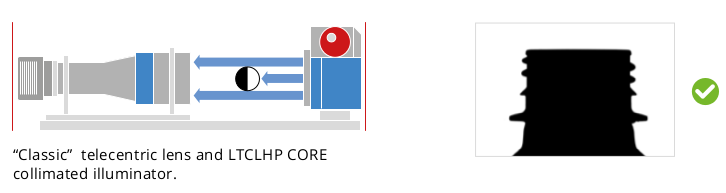

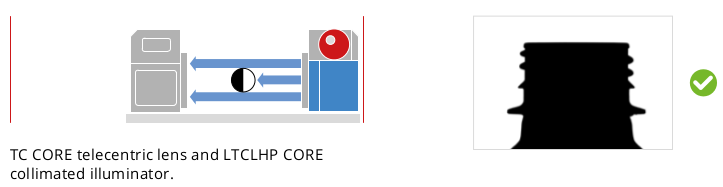

LTCLHP CORE illuminators can be used both with classic telecentric lenses and with ultra compact telecentric lenses from CORE family such as the TC CORE, TC2MHR CORE and TC4MHR CORE series.

DID YOU KNOW?

LTCLHP CORE series is now also available with new LTSCHP1W-GZ green light source, suitable for any kind of sample and specifically tailored for measuring reflective objects and objects with sharp edges.

KEY FEATURES

- Reduction of edge diffraction effects

- Enhanced illumination uniformity, especially on large FOVs

- Less sensitive to alignment

Ordering information

To order the version with the new green LED module use p/n

LTCLCRxxx-GZ (i.e. LTCLCR064-GZ)

Real-world application examples and case histories

Notes

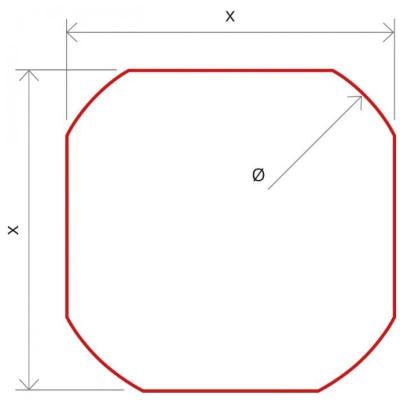

- Beam shape is not circular. See Tech Info for minimun beam dimensions.

- Opto Engineering® recommends green light for high precision measurement applications

- Tolerance ± 10%

- At max forward current. Tolerance is ± 0.06V on forward voltage measurements

- In continuous mode (non-pulsed)

- At pulse width <= 10 ms and duty cycle <= 10%. Built-in electronics board must be bypassed (see tech info)

- Nominal value, with no spacers in place

LTCLHP CORE - True collimated illumination in a reduced space

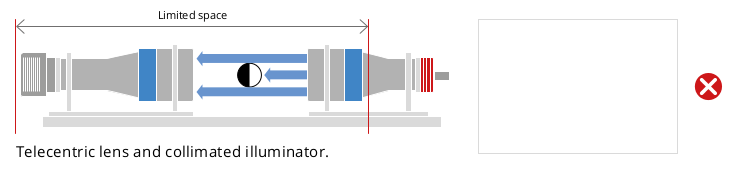

A standard collimated illuminator is impossible to use due to lack of space.

Classic solution with diffuse backlight: less precise measurements due to surface reflections and uncertain edge position.

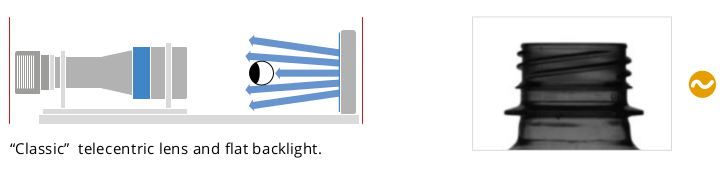

Smart solution with LTCLHP CORE telecentric illuminator: no edge uncertainty for excellent measurement results.

The smartest solution with TC CORE telecentric lens and LTCLHP CORE telecentric illuminator: excellent measurement results in a super compact space.