PCHI series

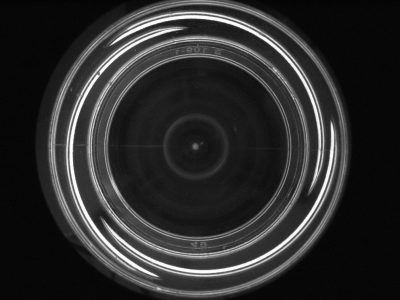

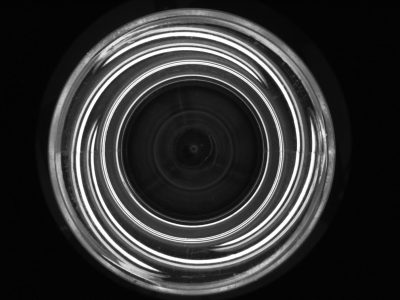

Hole inspection lenses for 360° inside view in perfect focus

New models of pinhole lenses available: PCHI3M, PCHI3M-AF and PCHI3M-MF for 1.1" sensors; PCHI012-AF and PCHI012-MF for 1/2" sensors with liquid lenses and manual focusing gear.

Key advantages

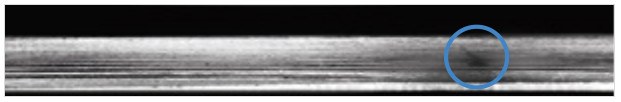

- Perfect focusing of holed objects

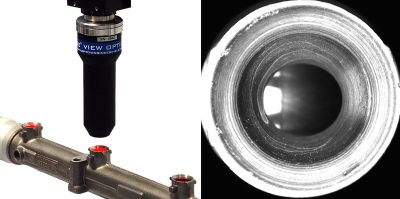

Both the walls and the bottom of a cavity are imaged in high resolution - Cavity inspection from the outside

No need to put an optical probe into the hole - Very high depth of field

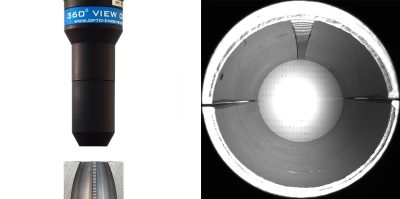

Objects featuring different shapes and dimensions can be imaged by the same lens - Wide angle of view

Sample surfaces are acquired by the lens under a convenient perspective to clearly display their features - New focusing ring version available

Manually adjusting the focus is never been easier! New integration with Optotune liquid lens technology

PCHI AF allows for an extremely fast and repeatable change in focus

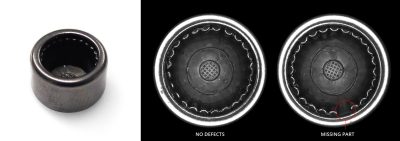

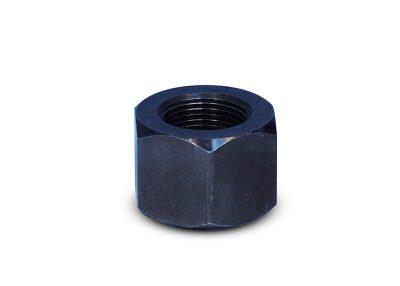

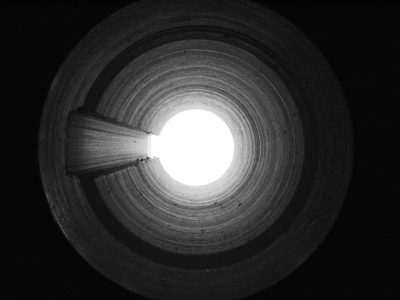

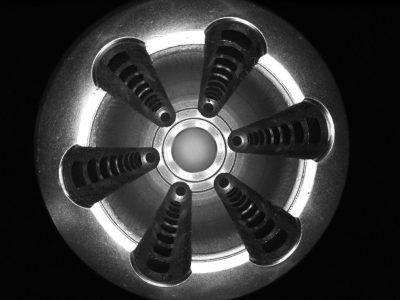

Real-world application examples and case histories

Notes

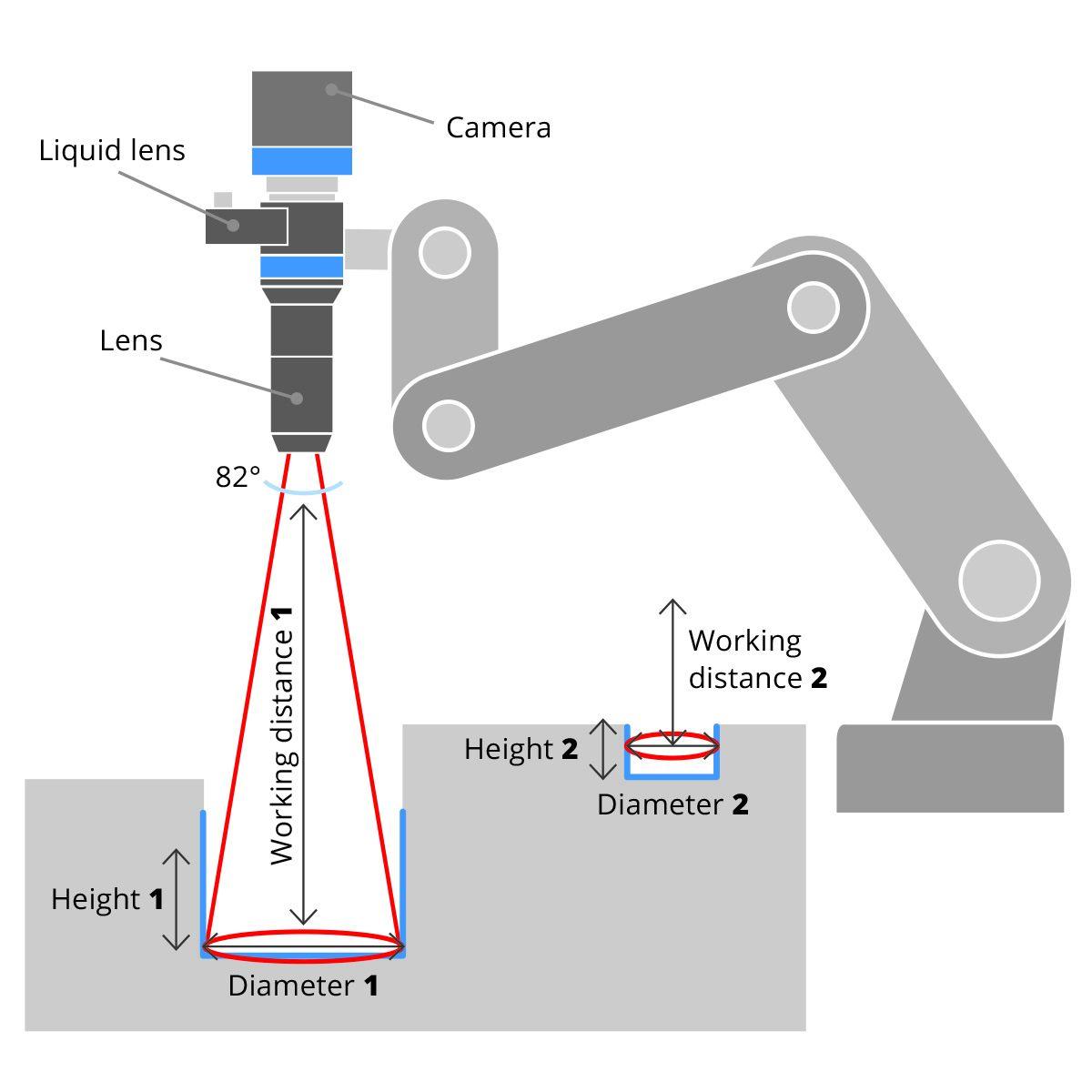

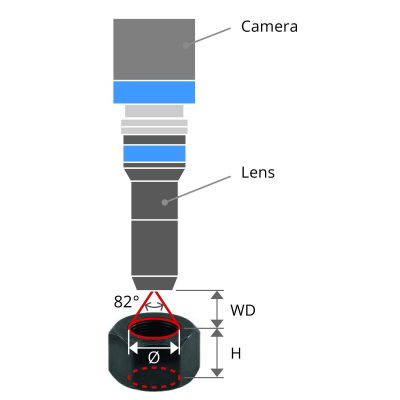

- Working distance: distance between the front end of the mechanics and the object.

- Working f-number (wf/N): the real f-number of a lens in operating conditions.

- Measured from the front end of the mechanics to the camera flange.

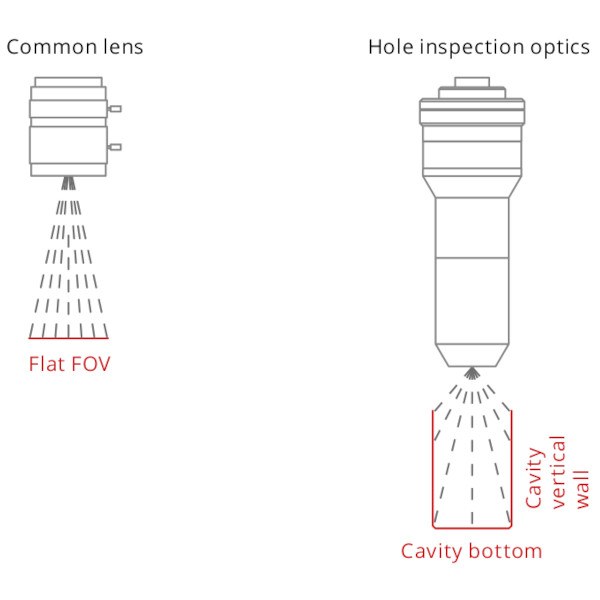

Working principle

PCHI optics can image cavities whose diameters and thicknesses span over a wide range of values.

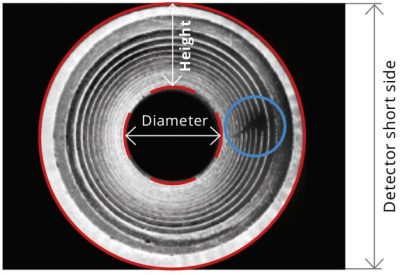

For a given hole diameter, the table below lists the maximum cavity height allowed for both high-resolution imaging (small pixel sizes) and normal resolution imaging (> 5 micron pixels) applications; the "r" ratio indicates how much of the detector area gets covered by the image of the hole inner walls.

The listed working distance values ensure that the object image is exactly inscribed into the short side of the detector, thus maximizing "r" ratio and image resolution.

Field of view selection chart

| PCHI013, PCHI012 and PCHI023 field of view | |||||

| Hole diameter (mm) | Cavity height (mm) | r (%) | Cavity height (mm) | r (%) | Working distance (mm) |

| 10 | 6 | 23.5 | 10 | 28 | 5 |

| 15 | 8.5 | 22.5 | 14.5 | 29 | 6.5 |

| 20 | 13 | 26.5 | 22 | 32.5 | 9 |

| 25 | 18 | 26 | 31 | 33 | 11 |

| 30 | 22 | 26 | 37 | 32 | 14 |

| 40 | 31 | 26.5 | 53 | 32 | 18 |

| 50 | 40 | 27 | 68 | 32 | 23 |

| 60 | 50 | 28.5 | 85 | 32.5 | 29 |

| 70 | 60 | 28 | 102 | 33 | 35 |

| 80 | 75 | 29.5 | 120 | 34 | 41 |

| 100 | 97 | 30 | 155 | 34.5 | 52 |

| 120 | 120 | 31 | 190 | 35 | 62 |