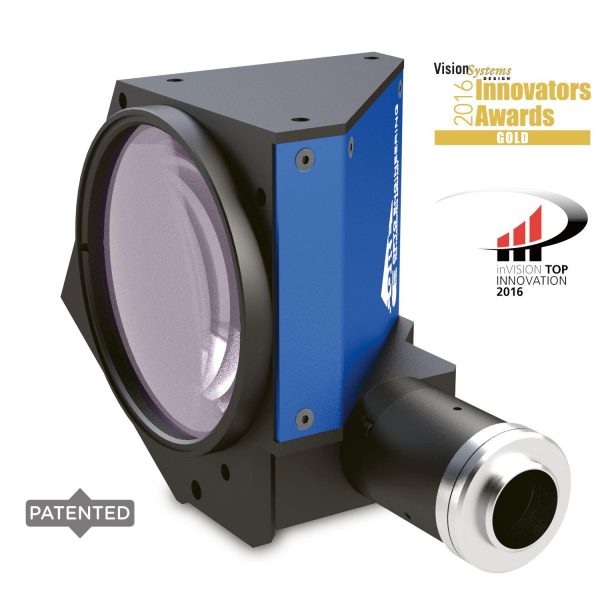

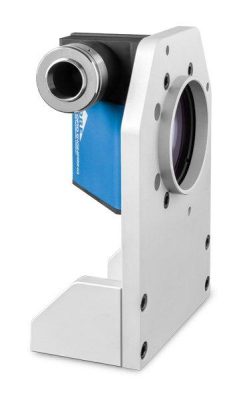

TC3MHR CORE series

Compact telecentric lenses for sensors up to 1.1”

Overview

Models

Downloads

Related

Tech Info

Resources

Magnification

0.118 - 0.303 x

Compact

Key advantages

- Excellent optical performances

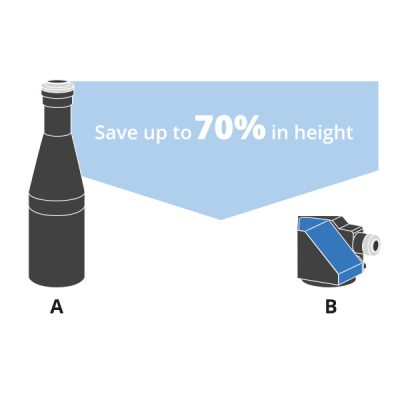

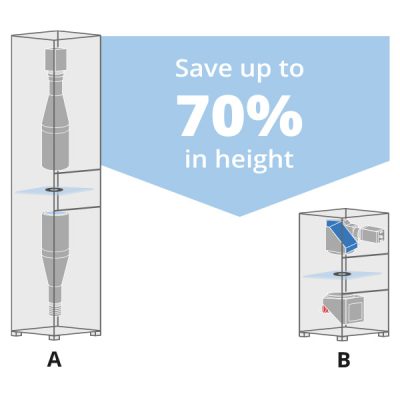

TC3MHR CORE telecentric lenses deliver excellent optical performances as other comparable Opto Engineering® telecentric lenses. - Extremely compact

TC3MHR CORE lenses are up to 70% smaller than other telecentric lenses on the market. - Designed for flexibility and smart integration

TC3MHR CORE lenses integrate a camera phase adjustment and can be mounted on multiple sides with or without clamps, allowing to cut costs. - Save you money

Systems integrating TC3MHR CORE lenses take much less space, resulting in lower manufacturing, shipping and storage costs. - Boost your sales

A smaller vision system or measurement machine is the solution preferred by the industry.

TC3MHR CORE series is a range of ultra-compact telecentric lenses tailored for high-resolution sensors up to 1.1”. TC3MHR CORE lenses deliver excellent optical performances in a super compact shape. Thanks to the unique opto-mechanical design, these lenses offer very high resolution, low F#, nearly zero distortion and high depth of field while saving up to 70% in length compared to similar FOV lenses on the market.

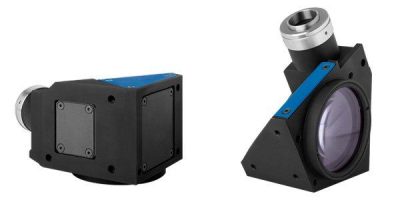

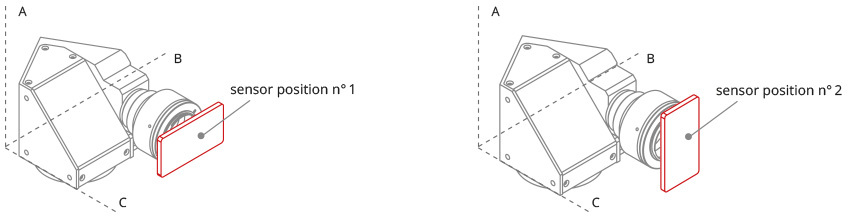

Thanks to the M6 threads located on multiple sides Opto Engineering® TC3MHR CORE lenses can be mounted in several orientations, even without clamping mechanics. For maximum flexibility, a special front mounting clamp is also available.

Discover more

ADVANTAGES

Cost reduction

- Lower manufacturing cost due to less material employed

- Less space required for storage and use

- Lower shipment expenses due to the smaller size

- Lower transportation risks

Sell more

- A smaller vision system or measurement machine is preferred by the industry

Please wait

Unable to process your request

Back to models

Filters

Close

Reset Filters

Notes

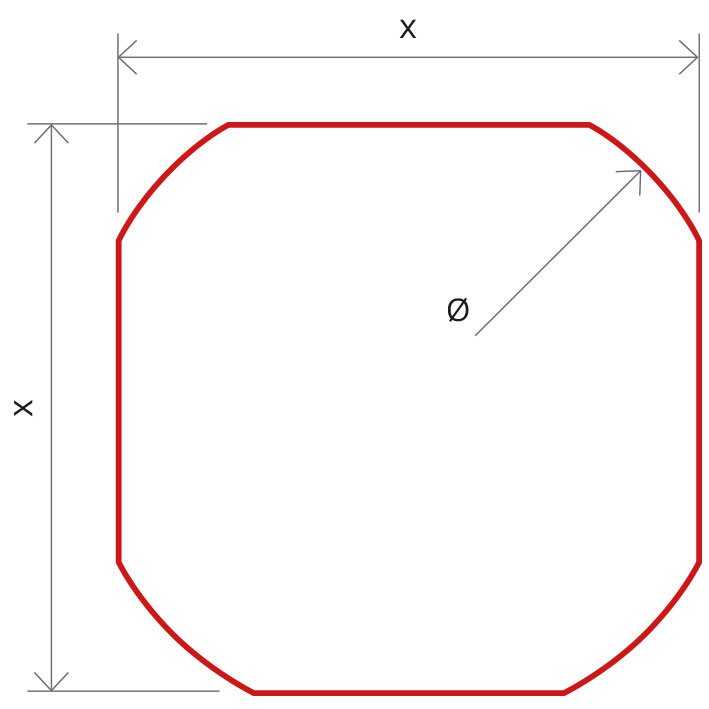

- Indicates the dimensions and shape of image, where "Ø =" stands for diameter and "x=" indicates the nominal image height and length (Tech Info for related drawing).

- Working distance: distance between the front end of the mechanics and the object. Set this distance within ± 3% of the nominal value for maximum resolution and minimum distortion.

- Working f-number (wf/N): the real f-number of a lens in operating conditions.

- Maximum angle between chief rays and optical axis on the object side. Typical (average production) values and maximum (guaranteed) values are listed.

- Percent deviation of the real image compared to an ideal, undistorted image. Typical (average production) values and maximum (guaranteed) values are listed.

- At the borders of the field depth the image can be still used for measurement but, to get a very sharp image, only half of the nominal field depth should be considered. Pixel size used for calculation is 3.45 μm.

- Object side, calculated with the Rayleigh criterion with λ= 520 nm

- Indicates the availability of an integrated camera phase adjustment feature.

- Due to the special shape of TCCR120xx it might be necessary to check the mechanical compatibility with your camera

Back to models