ITALA® cameras for high performance fasteners sorting machines

Case history Datagest

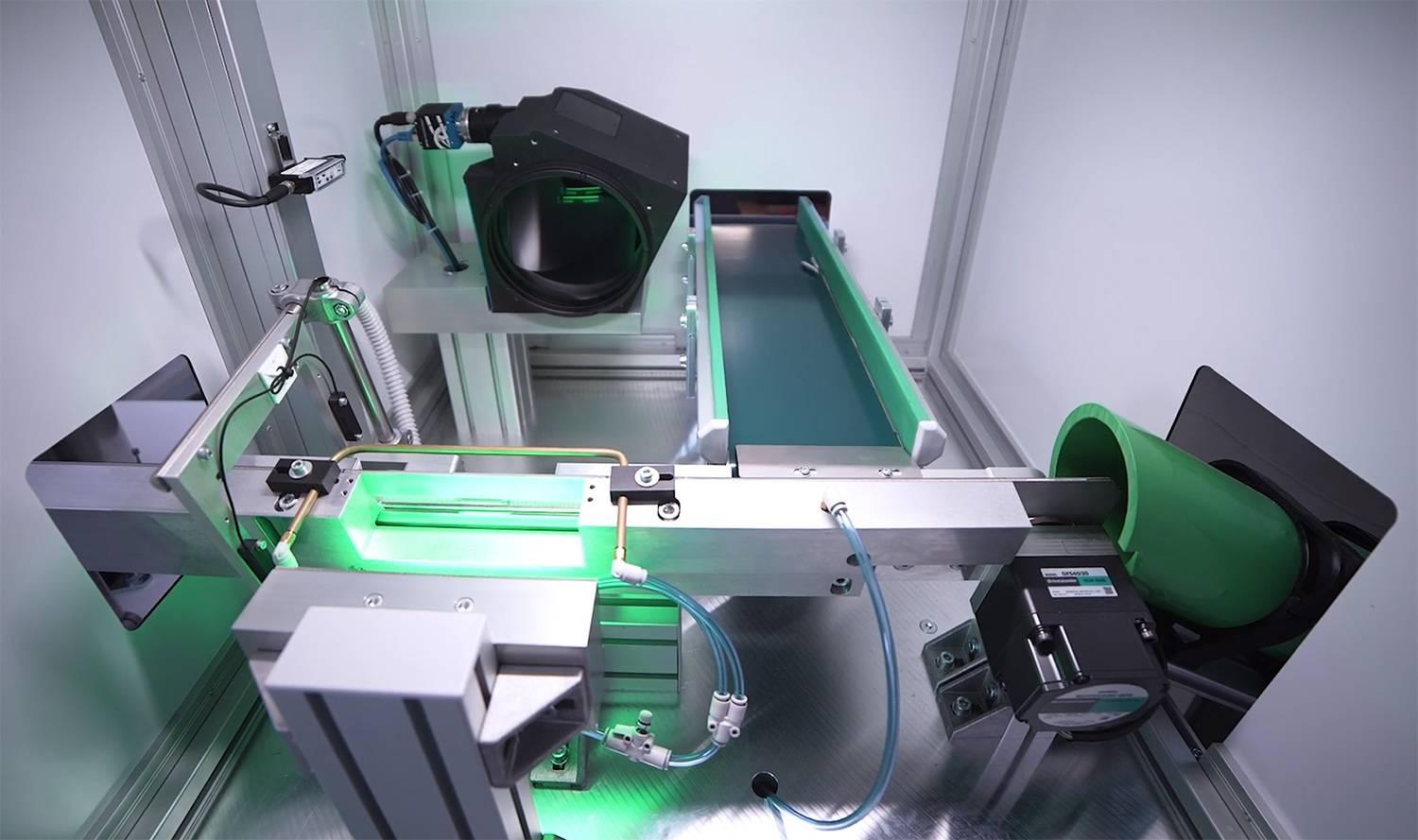

DGSORT is a 100% belt sorting system designed to inspect the size and shape of objects including screws, pins and bolts up to 120 mm in length. The system has sub-centesimal precision and reaches rates of up to 700 pieces per minute.

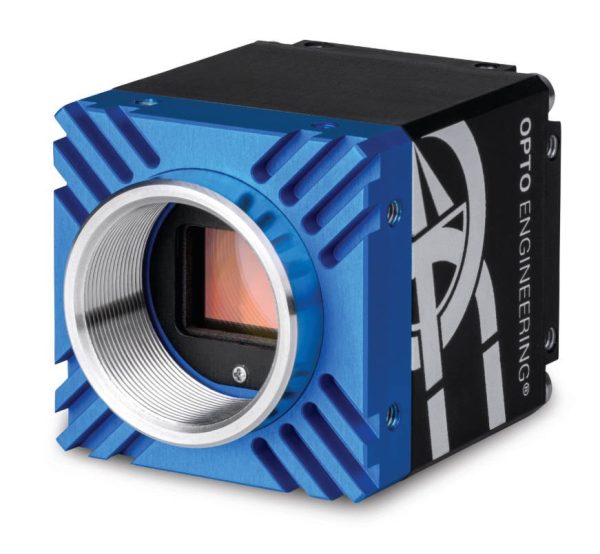

To ensure the desired performance, DGSORT integrates an ITA89-GM-10C camera with a 9 MP Sony Pregius sensor. In terms of optics and illumination, a combination of telecentric lenses and illuminators is used to achieve the high accuracy required. A traditional system for this type of field of view, however, would be rather bulky, which is why Opto Engineering's CORE technology was employed.

The case

Machine vision has a long tradition in the fastener industry. In fact, this industry typically requires a combination of high accuracy and throughput that only an automated system can achieve. Here we will discuss DGSORT, a high-performance sorting system that integrates ITALA® cameras by Opto Engineering®.

Why Opto Engineering®?

The greatest strengths found in ITALA® cameras are the extreme ease

of use and the completeness of the documentation provided. The latter,

in fact, guided the customer with precision and clarity during the

installation and configuration phases.

As with all other Opto

Engineering® products, the helpfulness, professionalism and speed of

the technical support received were instrumental in the realization of

the machine.