LTLNC series

Continuous LED line lights

Extended range New models now available in RED, BLUE, GREEN and IR wavelenghts (other wavelenghts available upon request).

Key advantages

- Ultra high power.

- Color matched white models.

- Condenser lens for a perfectly focused beam of light.

- Rugged industrial design with built in industrial connector

for easy integration into any machine vision system. - Forced air cooling option.

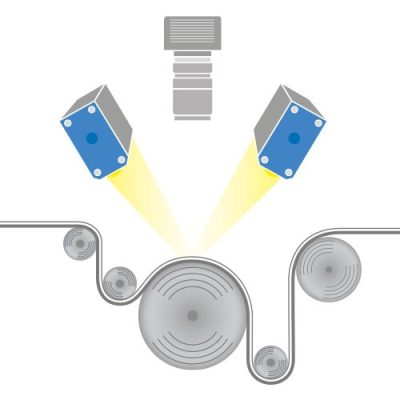

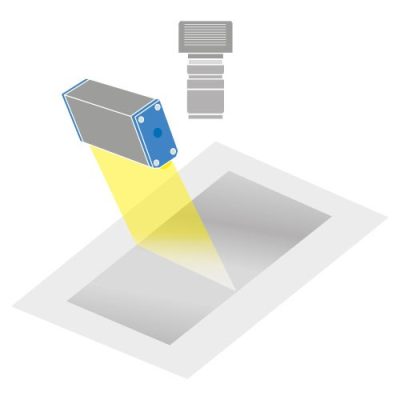

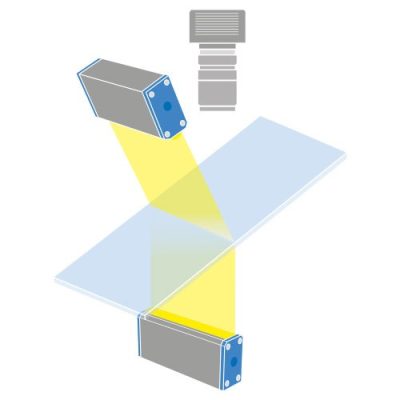

LTLNC series are ultra-high power LED line illuminators designed for line scan applications. Their special design provides both a powerful and homogeneous beam of light that is sharply focused onto the object that must be inspected, by means of a condenser lens.

LTLNC series can efficiently dissipate the generated heat thanks to the fins machined in the aluminum housing and the air cooling ports designed to inject compressed air into the illuminator.

Furthermore LTLNC series features industrial M8 connectors and can be easily installed into any machine vision system thanks to the four M3 threads in the rear part of the aluminum housing.

Notes

- Measured at minimum working distance

- ± 2%.

- With constant driving voltage.

- Drop to 50% intensity @ 25°C.

Technical documents

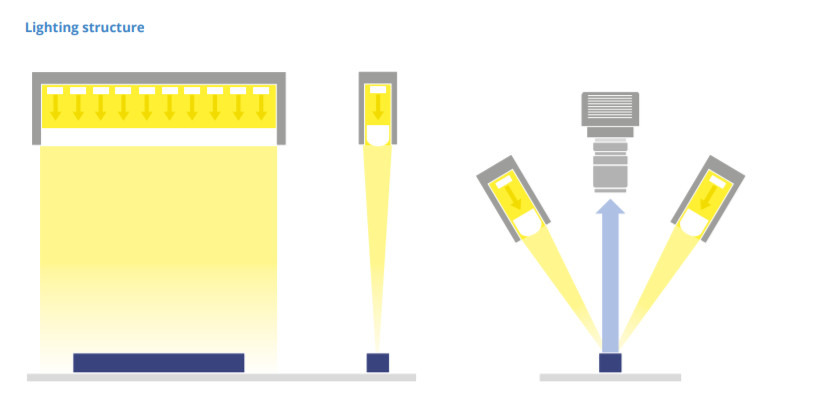

Light beam coarse adjustment

Simply untighten the lateral screws to adjust the axial position of the condenser lens

N.B. When the position is set, do not overthighten the screws to avoid damage to the condenser lens.